TOP

TOP

ANYDESIGN

ANYDESIGN

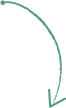

Unlike a typical design program, AnyDESIGN allows you to set materials for the product, mold, core and chiller components. It includes all thermal properties such as density, specific heat, and conductivity of materials in the program providing users with additional information other than design and is used as an important resource for calculating real-time verifiable design plan information.

Library functionality also automatically saves user usage patterns for more convenient settings.

Quickly edit your design

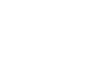

Based on the product thickness, the final solidification area can be easily identified during melt solidification without modulus calculation or commonly used casting analysis.

Use the Thickness Map feature to provide designers with critical information and minimize design time in the runner design, especially in the riser design.

Idea sketches drawn with the designer’s initial thoughts can be filed and used as a design within the program.

It has the significant effect of reducing the initial design time by easily locating the sprue, runner, riser, riser neck, etc.

Quickly edit your design

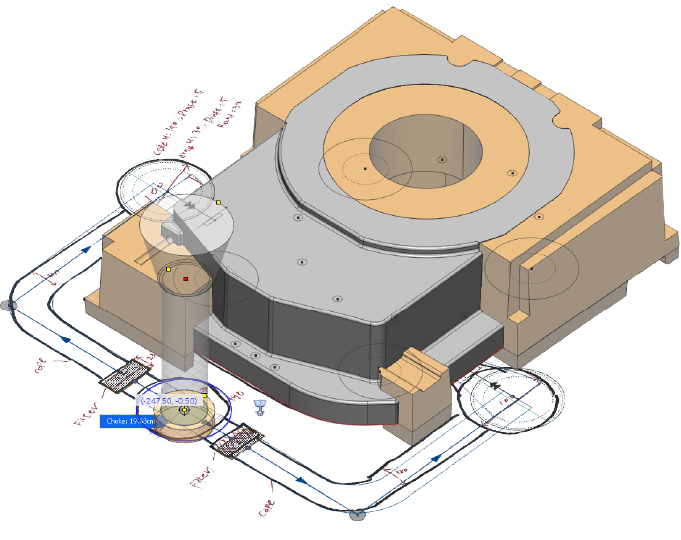

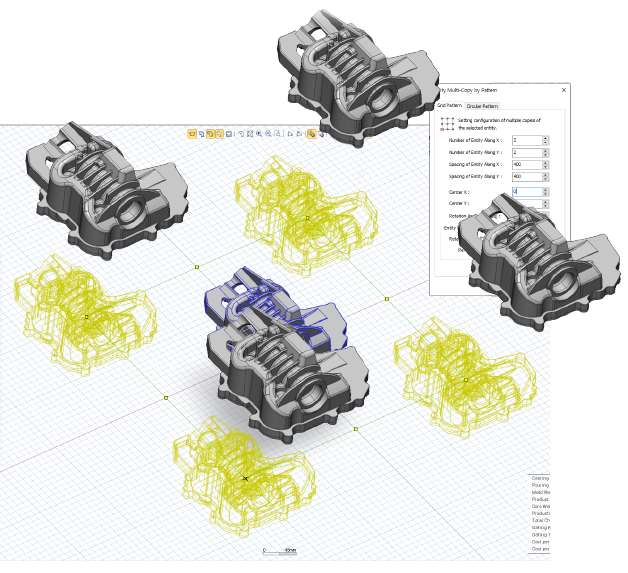

Above two cavity design allows quick and easy product arrangement such as squares and circles.

Using one product modeling, users can arrange different products within the flask size with simple numerical inputs, such as the number of products, spacing, and rotation angle between each product based on each axis direction and center coordinates.

Quickly edit your design

The most important factor when designing a plan is to proceed with the design after dividing cope and drag based on the parting line. AnyDESIGN provides information about the parting line to designer so that they can figure the accurate location in each design element.

It is also possible to set a flat parting line and a stepped parting line, and whether to connect an ingate is determined according to the parting line.