TOP

TOP

ANYDESIGN

ANYDESIGN

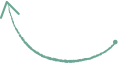

AnyDESIGN is a design program specializing in casting plans, and unlike other CAD programs, user can check design plan information in real time when designing a plan.

It is possible to minimize design errors by monitoring key items to be checked in real time, such as the required amount of melt, weight of mold and core, recovery rate, expected shrinkage rate, total choke area, and gating ratio.

Quickly edit your design

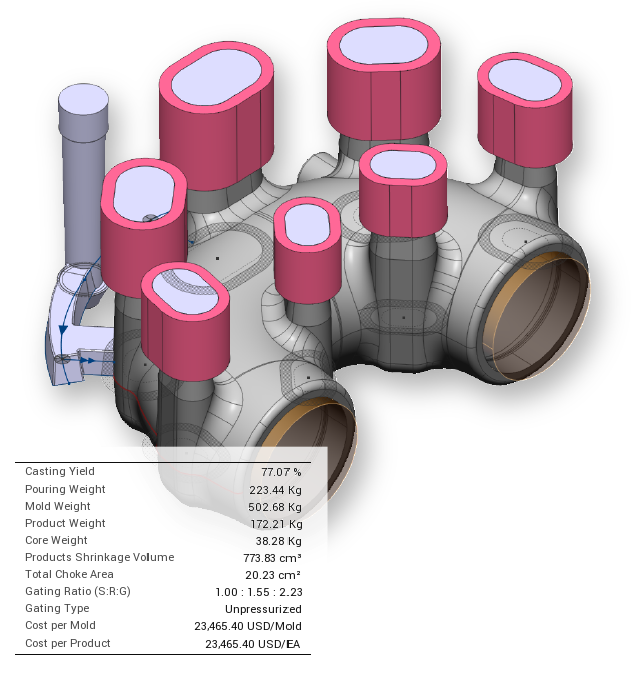

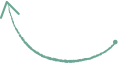

The proper distance between the ±X, ±Y, ±Z axes and the outermost wall of the mold based on the entire casting method is important to maintain the mold strength. The soundness is judged by measuring the distance between the final finished casting plan and the outer wall of the mold by referring to the minimum mold wall thickness distance set by the user at the initial design stage.

Starting from the user-specified parting line point, measure the height of the top of the product and riser. In order to maximize the feeding effect, it should have an effective height for feeding during solidification, the basic effective height must be higher than the minimum product height at the top of the riser.

The ‘Height of Product and Riser’ function verifies the soundness of the riser design based on the above theory.

Quickly edit your design

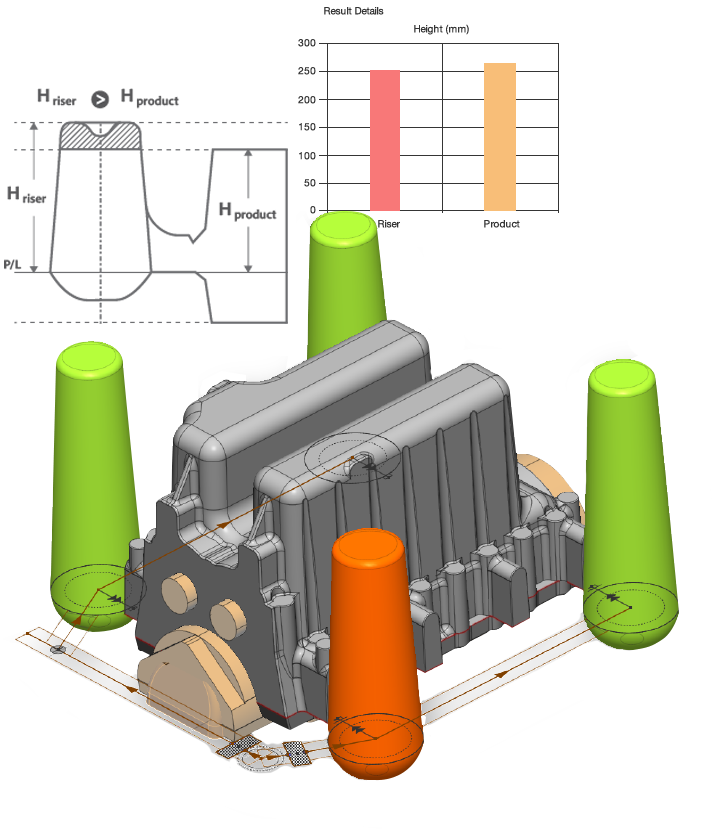

By calculating the amount of liquid shrinkage between the designed riser and the product, it can be judged whether the liquid shrinkage compensation using the riser can be properly compensated.

The liquid shrinkage is calculated by multiplying the liquid shrinkage coefficient by each volume, using the material database and pouring temperature setting information that user set when designing the initial plan.

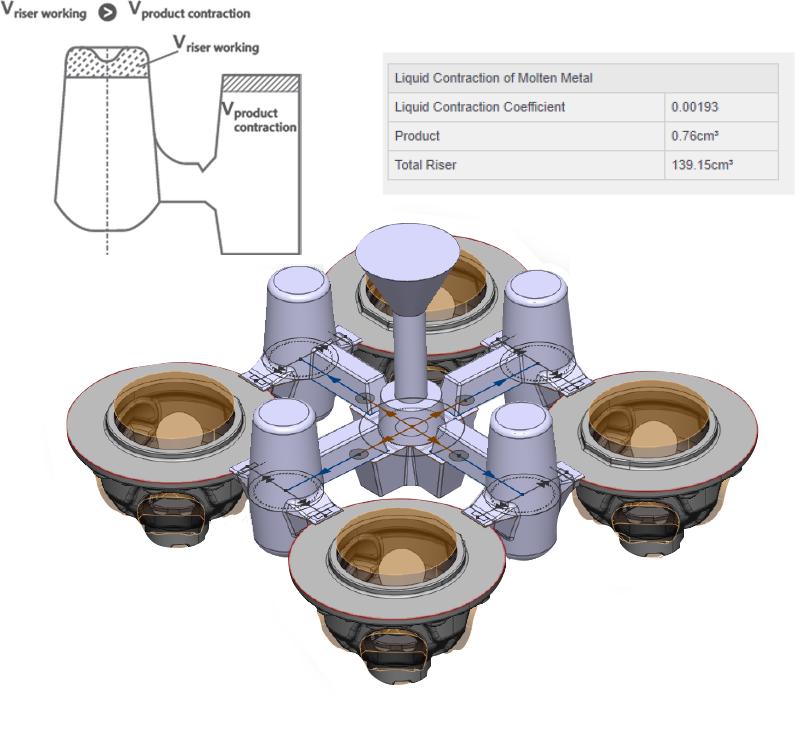

It is judged whether adequate shrinkage compensation can be achieved by comparing the shrinkage rate of the installed riser against the Shrinkage rate of the product during solidification. The shrinkage rate of the product uses the information in the set material database, In the case of riser, it is calculated by applying a separate feeding ratio according to the type of riser using an exothermic sleeve, blind riser, or internal riser.

Quickly edit your design

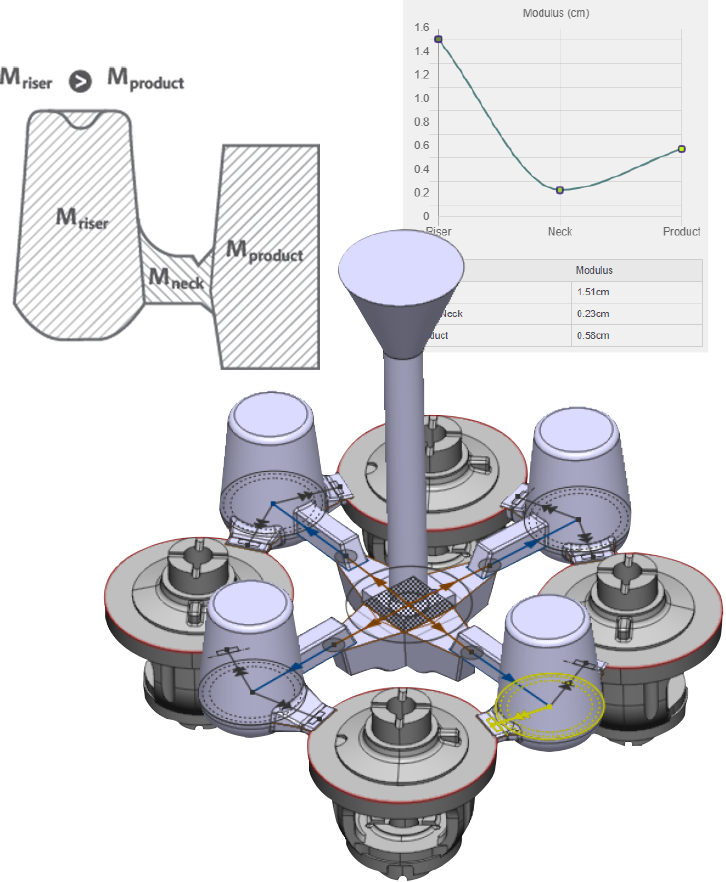

The first thing to consider when designing a riser installed to compensated for shrinkage defects occurring within the product is to check the modulus between each element. It is a major check before design because it can be judged that there is no effect of compensation for shrinkage defects when the modulus of the designed riser is smaller than the product.

AnyDesign automatically handles this process and evaluates the soundness of the plan by comparing the modulus results of the product, riser, and riser neck against the design plan.